Maintaining plant uptime isn’t just about fixing machines when they break. The goal is to avoid malfunctions altogether. That’s where Rotary Equipment Maintenance Contractors come in. These experts perform specialized tasks that keep your rotary systems like pumps, compressors, and turbines running smoothly-reducing unexpected downtime and improving safety.

In this blog, we’ll explore the top 10 tasks performed by these contractors, specific types of rotary equipment they maintain, the benefits of regular maintenance, and address commonly asked questions.

Let’s dive in.

What is the Maintenance of Rotating Equipment?

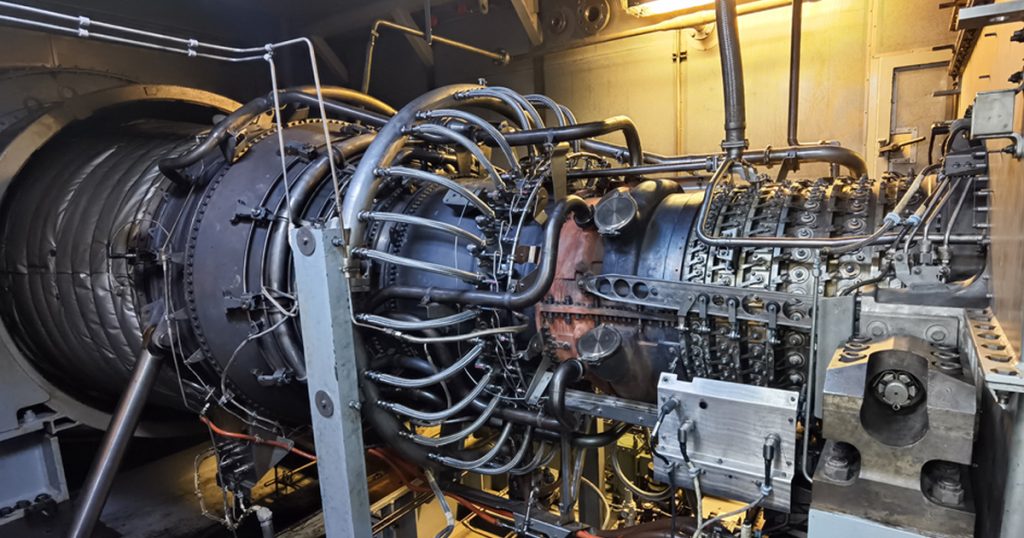

Machines with moving parts usually those that spin or rotate, like motors, pumps, gearboxes, turbines, and compressors are referred to as rotating equipment.

Maintenance of rotating equipment includes routine checks, lubrication, vibration monitoring, alignment adjustments, and full overhauls. The goal is to:

- Prevent breakdowns before they occur

- Optimize equipment performance

- Ensure safety and compliance

Unlike static machinery, rotating systems experience high wear due to friction, heat, and mechanical stress. That’s why they require more frequent and specialized attention.

What Type of Cost is Equipment Maintenance?

Equipment maintenance costs are considered Operational Expenses (OPEX).

While these costs are ongoing, they are essential to:

- Prolong equipment life

- Avoid emergency repairs

- Reduce unplanned downtime

- Prevent large Capital Expenses (CAPEX)

In short, investing in regular maintenance saves you far more money in the long run than reactive repairs.

Who is Responsible for Equipment Maintenance?

Typically, routine tasks are handled by in-house maintenance teams. However, Rotary Equipment Maintenance Contractors are brought in for:

- Specialized diagnostics

- Predictive or condition-based monitoring

- Shutdown maintenance

- Overhauling complex machinery

They bring in specific tools, methodologies, and a higher level of expertise-especially during high-stakes situations where performance and safety cannot be compromised.

What is Routine Maintenance of Equipment?

Routine maintenance includes simple, periodic checks that ensure rotary machines are functioning efficiently. These tasks include:

- Lubrication – Keeps moving parts smooth and reduces wear

- Cleaning – stops dust and particles from causing component damage

- Fastener Tightening – Ensures bolts and parts stay secure

- Visual Inspections – Spots leaks, cracks, and rust early

- Alignment Checks – Ensures shafts and belts run in straight paths

These tasks are typically performed daily, weekly, or monthly-depending on machine type and usage. For more technical insights into maintaining rotating systems, our post on rotary services offers practical strategies used in top-tier plants.

What is the Main Component of the Rotary System?

The spinning shaft is the central component of any rotary system.

It transmits mechanical energy and is supported by several critical parts:

- Bearings – Allow smooth shaft rotation

- Seals – Prevent lubricant leaks and block contamination

- Couplings – Connect the shaft to motors or load systems

- Housing – Protects internal components from external damage

If any of these parts fail, it can result in equipment shutdown or mechanical damage. That’s why these components are regularly inspected by skilled maintenance professionals.

Types of Rotary Equipment Maintenance Services You May Need

When working with professional Rotary Equipment Maintenance Contractors, these are the key services you can expect:

- Overhauling and Repair

Complete disassembly, inspection, part replacement, and reassembly to restore equipment functionality. - Preventive Maintenance

Scheduled tasks to avoid breakdowns-includes inspections, tightening, and lubrications. - Vibration Analysis

Detects signs of imbalance, misalignment, or failing bearings using sensor-based monitoring. - Lubrication Management

Establishes proper intervals and types of lubricants to minimize friction and maximize part life. - Laser/Dial Alignment

Ensures shafts and couplings are perfectly aligned to reduce wear and vibration. - Reverse Engineering

Reproduces obsolete parts when replacements are unavailable, extending the equipment’s lifespan. - Condition Monitoring

Uses sensors and software to track temperature, vibration, and load in real-time. - Shutdown Maintenance

Comprehensive servicing during planned shutdowns to overhaul multiple machines efficiently. - Troubleshooting

Rapid diagnosis and resolution of abnormal equipment behavior, reducing delays.

These services are tailored based on your operational setup, asset type, and industry-specific needs. For a deeper look into our full suite of support services, explore our Rotary Equipment Services to see how we tailor maintenance to each industry’s demands.

Specific Examples of Rotary Equipment Contractors Maintain

Rotary Equipment Contractors typically handle various equipment types across industries. Here are the most common ones:

- Pumps

Used for fluid movement-require seal checks, impeller inspection, and alignment. - Compressors

Handle gas compression-need constant vibration checks and thermal monitoring. - Gearboxes

Transfer motion between systems-require oil level checks and gear inspections. - Fans and Blowers

Manage airflow and cooling-need periodic balancing and lubrication. - Turbines

Generate energy from fluid flow-require precision alignment and vibration monitoring.

Each piece of equipment has unique requirements, but all play a critical role in maintaining operational efficiency.

Benefits of Regular Maintenance

Why invest in regular maintenance? The benefits are long-term and measurable:

- Reduced Downtime

Scheduled maintenance prevents unexpected stoppages and delays. - Extended Equipment Life

Well-maintained machines operate longer with fewer part replacements. - Improved Efficiency

Clean, well-lubricated, and aligned machines run faster and use less energy. - Cost Savings

Preventive measures cost less than emergency repairs or full replacements. - Enhanced Safety

Reduces risk of accidents, overheating, or catastrophic mechanical failures.

Your ROI increases significantly when maintenance is consistent and proactive.

Frequently Asked Questions (FAQs)

What Do Rotary Equipment Maintenance Contractors Do?

They provide expert services such as alignment, diagnostics, overhauls, and condition monitoring for rotating equipment to ensure peak uptime and performance.

How Often Should I Schedule Maintenance?

This depends on your equipment type and usage, but most facilities benefit from a monthly or quarterly routine combined with annual shutdown maintenance.

Are There Any Industry Standards for Maintenance?

Yes. Many contractors follow ISO standards and OEM-recommended schedules, especially for critical systems like turbines and compressors.

Can Contractors Handle Emergency Repairs?

Absolutely. Most top-tier contractors offer 24/7 support and can deploy teams quickly during emergencies or shutdowns.

Why Rotary Maintenance Isn’t Optional

Rotary machinery is the heart of many industrial plants, and its failure can lead to unplanned downtime, safety hazards, and costly repairs. By partnering with professional Rotary Equipment Maintenance Contractors, businesses gain access to technical expertise, advanced diagnostics, and preventive strategies that help extend equipment lifespan and boost operational efficiency.

Whether you’re planning a shutdown, investigating vibration anomalies, or simply aiming for uninterrupted uptime, professional support makes all the difference. Consistent and strategic maintenance isn’t an expense-it’s an investment in long-term productivity and plant health.

Their ability to handle diagnostics, preventive care, and complex repairs brings lasting value to your business. Want to explore how we support your operations beyond rotating equipment? Check out our complete list of industrial maintenance and engineering services.