In industries such as oil & gas, petrochemicals, fertilizers, and power generation, many companies depend on skilled Rotary Equipment Maintenance Contractors in Oman to keep their plants running smoothly. Pumps, compressors, turbines, and blowers are vital rotating machines that must operate reliably to support continuous production.

Rotating equipment accounts for a significant share of plant downtime when not maintained properly. Issues like misalignment, vibration, seal failures, and lubrication problems can reduce efficiency and cause unplanned outages. By partnering with specialized contractors, industries not only safeguard productivity but also align with global standards in safety, environmental compliance, and performance.

What is rotary maintenance?

Rotary maintenance refers to the systematic upkeep, inspection, and repair of rotating machinery used in industrial plants. It involves preventive and predictive techniques such as vibration analysis, oil analysis, infrared thermography, and performance benchmarking.

The primary goal is to detect problems before they escalate into breakdowns. For example, monitoring bearing temperatures helps identify early signs of friction and wear, allowing engineers to intervene before catastrophic damage occurs. Similarly, vibration monitoring reveals misalignments, imbalances, or looseness in equipment that could shorten asset life.

By applying these strategies consistently, rotary maintenance ensures optimal uptime, reduces energy consumption, and extends the service life of critical machinery.

What is the maintenance of rotating equipment?

Maintenance of rotating equipment combines both preventive actions and corrective measures. Preventive actions include periodic inspections, lubrication management, alignment checks, and replacing worn parts at scheduled intervals. Corrective measures involve repairing or overhauling equipment when it no longer meets performance standards.

With advancements in technology, predictive maintenance tools like AI-driven monitoring systems and IoT-based sensors are now being widely adopted. These tools provide real-time health monitoring, enabling industries to optimize maintenance schedules and avoid unnecessary downtime.

Industries such as power generation and petrochemicals particularly benefit from advanced maintenance strategies, as even a minor failure in a turbine or compressor can result in multi-million-dollar losses.

What is rotary equipment?

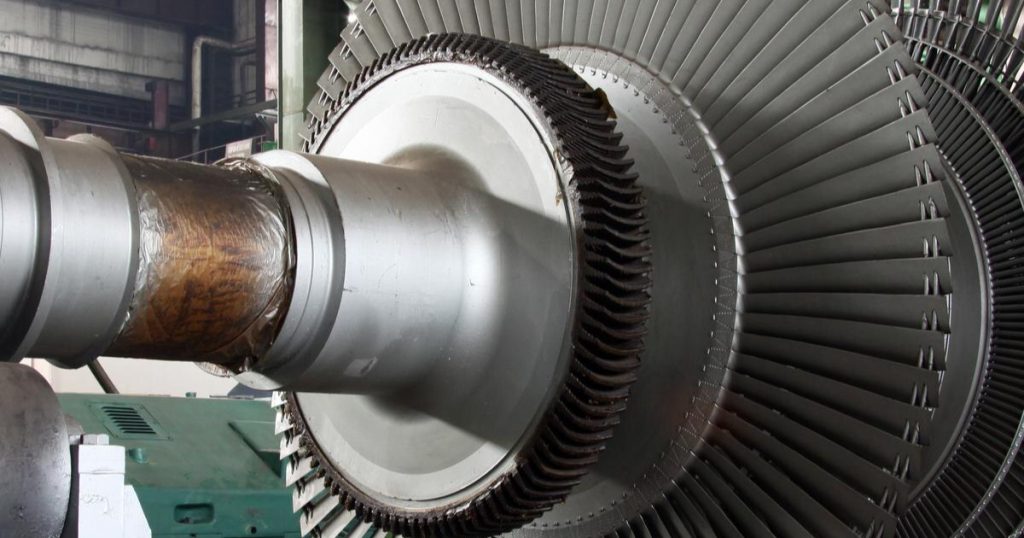

Rotary equipment refers to all machinery with moving or rotating components that transfer energy, move fluids, or produce power. Common examples include:

- Pumps: Carry liquids, including chemicals, water, and oil.

- Compressors: Increase the pressure of gases for processing and transportation.

- Fans and Blowers: Circulate air or gases in controlled environments.

- Turbines: Generate power or drive compressors.

These machines form the backbone of industrial plants. Their performance directly impacts productivity, safety, and operating costs. This is why commissioning, maintenance, and overhaul of rotary equipment are considered high-priority services across critical industries.

The role of specialized contractors

Engaging skilled service providers like Rotary Equipment Maintenance Contractors in Oman helps industries achieve consistent reliability and efficiency. These contractors bring specialized knowledge, advanced diagnostic tools, and adherence to international codes such as API, ISO, and ASME.

They manage the entire lifecycle of rotary machinery from installation and commissioning to predictive maintenance and eventual overhauls. Their expertise ensures that assets are not only installed correctly but also maintained with precision. By doing so, industries reduce unplanned failures, optimize energy usage, and ensure compliance with regulatory frameworks.

Rotary Equipments Shutdown

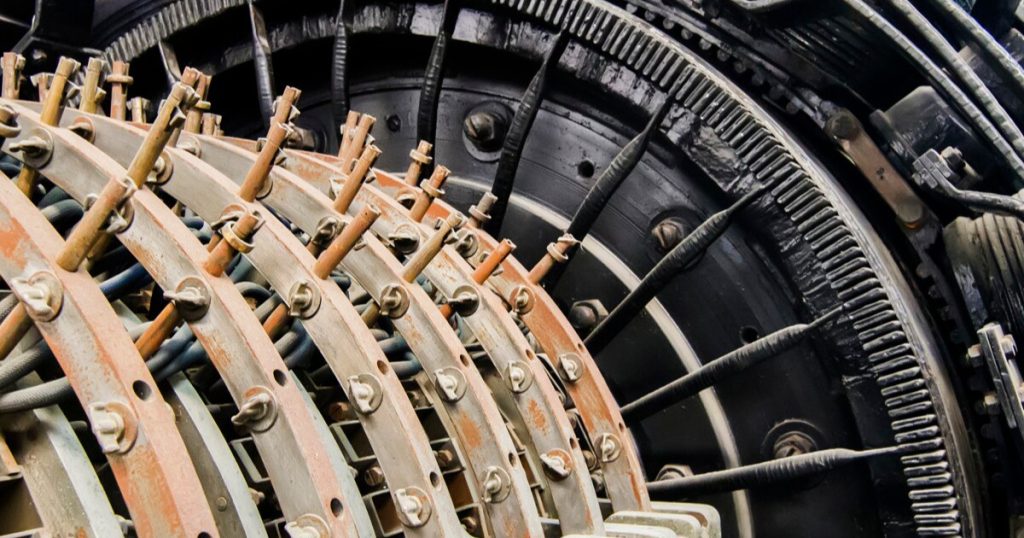

One of the most crucial services offered by contractors is managing Rotary Equipments Shutdown periods. Planned shutdowns are scheduled to perform thorough inspections, replacements, and system upgrades without disrupting long-term operations.

During these shutdowns, equipment is carefully disassembled, cleaned, inspected, and tested for hidden faults. Components like bearings, seals, couplings, and gears are replaced if necessary. Shutdowns also allow for integration of new technologies or design upgrades that enhance performance.

By managing shutdowns effectively, industries ensure that machinery is restored to peak condition while minimizing the risk of unexpected breakdowns.

Rotary Equipments Overhauling

Overhauling is a major process in which rotary machinery is dismantled, refurbished, and restored to original performance specifications. Rotary Equipments Overhauling may include rebalancing rotors, replacing damaged blades in turbines, rewinding motors, or repairing compressor impellers.

This process is often carried out when machinery reaches the end of its service cycle or fails to deliver required performance. Overhauling not only extends the life of equipment but also reduces replacement costs.

When handled by expert contractors, the overhaul process ensures alignment with OEM (Original Equipment Manufacturer) guidelines and helps maintain warranty validity.

Rotary Equipment Installation & Commissioning

Every piece of rotating machinery must be installed and tested with precision to guarantee safe and efficient operation. Rotary Equipment Installation & Commissioning involves foundation checks, alignment, lubrication setup, vibration baseline testing, and integration with control systems.

During commissioning, contractors verify that equipment meets design specifications for pressure, flow, and temperature. Instrumentation loops are calibrated, safety interlocks are tested, and performance is documented.

By ensuring correct installation and commissioning, industries significantly reduce the chances of premature equipment failure and costly downtime.

FAQs

What training is needed for rotating equipment?

Handling rotary machinery requires specialized technical training. Engineers and technicians undergo courses in vibration analysis, condition monitoring, laser alignment, lubrication management, and thermography.

Training also covers international codes and standards to ensure compliance during installation, inspection, and maintenance. In addition, hands-on workshops prepare professionals to troubleshoot real-world scenarios, making them adept at minimizing risks during plant operations.

What is an overhaul of equipment?

An overhaul of equipment refers to the complete refurbishment of machinery to restore it to near-original condition. It may involve stripping the equipment down, replacing worn parts, rebalancing rotors, recalibrating systems, and testing performance against original design standards.

Overhauls are often more cost-effective than full replacements and help industries extend asset life by several years. Contractors document every step of the overhaul, ensuring traceability and compliance with safety and quality standards.

What is the KPI for rotating equipment?

Key Performance Indicators (KPIs) are used to track the health and performance of rotating machinery. Common KPIs include:

- Mean Time Between Failures (MTBF)– Measures equipment reliability.

- Overall Equipment Effectiveness (OEE)– Evaluates availability, performance, and quality.

- Maintenance Cost per Unit of Production– Tracks efficiency of maintenance spending.

- Energy Efficiency Metrics– Identifies opportunities for cost savings.

Monitoring KPIs helps industries make informed decisions about maintenance strategies and investment planning.

What is particularly important when inspecting rotating equipment?

During inspections, attention must be given to:

- Alignment and balance of rotating shafts.

- Condition of bearings, seals, and couplings.

- Lubrication quality and levels.

- Vibration and noise patterns.

- Structural integrity of foundations.

Regular inspections help detect early faults and prevent catastrophic failures. Contractors use advanced diagnostic tools to carry out these inspections with accuracy.

Long-term value of expert contractors

By working with seasoned Rotary Equipment Maintenance Contractors in Oman, industries benefit from a holistic approach that combines installation, predictive maintenance, overhauls, and shutdown management. These services ensure that assets operate at peak efficiency, downtime is minimized, and operational costs are reduced.

The long-term value lies not just in equipment reliability but also in enhanced workforce safety, compliance with global standards, and sustainable industrial growth.

Building Reliability Through Expertise

The health of rotating machinery directly impacts the success of industries worldwide. From oil & gas to fertilizers and power generation, reliable operation is possible only with precise installation, scheduled maintenance, and expert care. That’s why engaging Rotary Equipment Maintenance Contractors in Oman is not just a service choice, it’s a strategic investment in safety, productivity, and efficiency.

By combining advanced diagnostic tools, technical expertise, and adherence to international standards, these contractors help industries maximize uptime and extend the lifecycle of critical assets. The result is a safer, more efficient, and future-ready industrial ecosystem.

Looking for reliable industrial solutions? Explore our full range of services on the Swamina International Homepage.